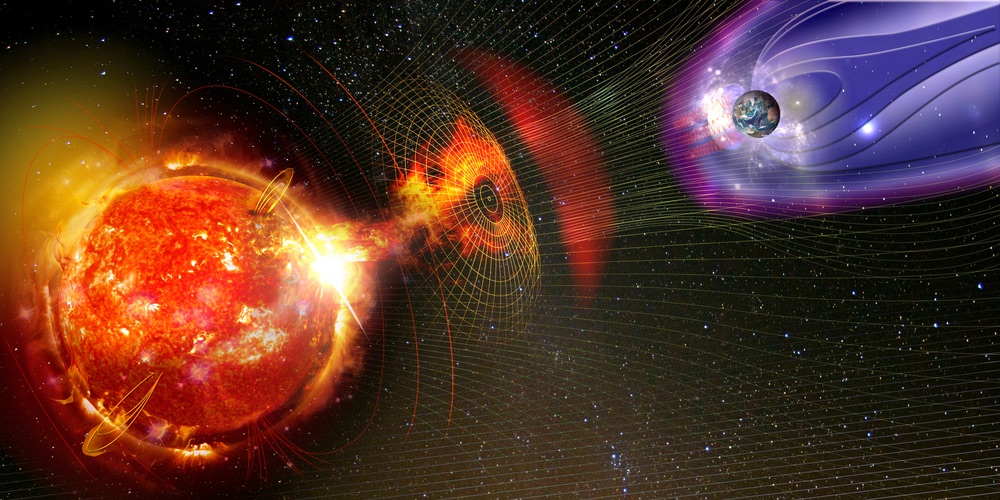

Ongoing geomagnetic storms, fueled by intense solar activity, pose significant threats to the myriad of satellites (such as SpaceX Starlink) orbiting Earth. These storms, which result from bursts of solar wind and magnetic fields interacting with Earth’s atmosphere, can disrupt satellite operations by damaging electronic circuits and disrupting communication channels. The effects can range from temporary loss of satellite functionality to severe, permanent damage that can cripple critical infrastructures for navigation, weather forecasting, and global communications.

Satellites face increased risks of high-energy particle exposure, which can degrade solar cells and shorten their operational life. Additionally, the enhanced radiation can interfere with the onboard electronic systems, potentially leading to data loss or erroneous signals. Operators often have to switch satellites to safe modes, limiting their functionality to prevent irreversible harm during severe solar events.

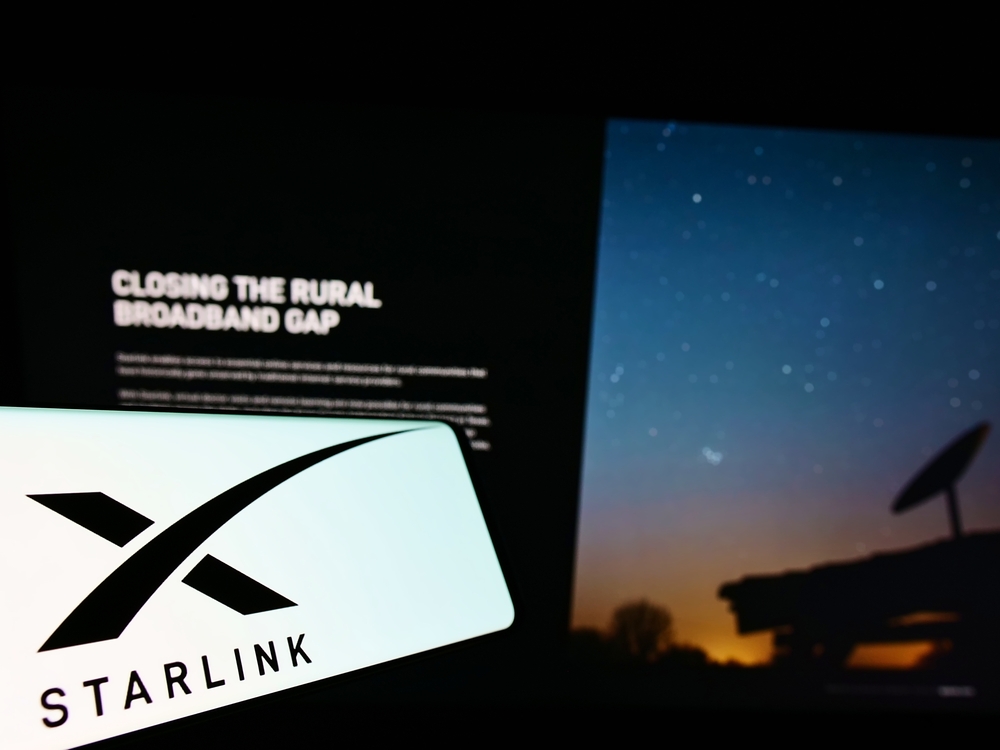

In response to these challenges, companies like SpaceX have engineered their satellites, such as the Starlink constellation, with resilience in mind. SpaceX’s approach integrates robust material selection, advanced engineering designs, and autonomous management systems that enable their satellites to withstand and adapt to the harsh conditions posed by geomagnetic storms. This focus on durability and adaptive capability illustrates SpaceX’s commitment to maintaining service continuity and reliability, even under the most adverse space weather conditions.

SpaceX employs several materials and design techniques to enhance the resilience of Starlink satellites against geomagnetic storms and other space weather conditions. While the specific material composition details of the Starlink satellites are proprietary, some commonly used materials and methods in satellite technology that enhance storm resistance include:

- Aluminum Alloys: Many satellites, including those in the Starlink constellation, use aluminum alloys for the primary structure due to their strength-to-weight ratio, cost-effectiveness, and resistance to the space environment.

- Multi-Layer Insulation (MLI): Satellites are often wrapped in multi-layer insulation that protects against the harsh conditions of space, including thermal extremes and radiation. This insulation can help mitigate the effects of increased radiation during solar storms.

- Tantalum or Tungsten: Critical electronic components might be shielded with heavy metals like tantalum or tungsten that provide effective radiation shielding.

- Silicon Carbide (SiC) and Gallium Nitride (GaN): These materials are used in semiconductor devices for their high heat resistance and ability to operate under extreme conditions. They are particularly effective in power electronics and high-frequency devices.

- Conductive Coatings: Electrostatic discharge coatings and other conductive materials can protect the external surfaces of the satellite from accumulating charge, which can be a significant risk during magnetic storms.

- Redundant Systems: While not a material per se, incorporating redundancy in critical systems and components ensures that if one element is damaged by a solar storm, others can take over its function.

SpaceX likely combines these materials with sophisticated design techniques to ensure that Starlink satellites can withstand the various challenges posed by their low Earth orbit environment, including exposure to solar radiation and geomagnetic storms.