In our world today, lithium is incredibly important because it powers many of the things we use every day, like smartphones, laptops, and electric cars. Most of this lithium comes from the ground, and getting it out can be a tricky business. That’s where Direct Lithium Extraction (DLE) comes in. This method is a cleaner and more efficient way to get lithium than traditional methods. Let’s explore what DLE is, how it works, and why it’s changing the way we get lithium.

What is Lithium?

First, let’s talk about lithium itself. Lithium is a very light metal and reacts quickly with other elements. It’s found in the earth’s crust and is usually obtained from rock or from salty water (brine) beneath the ground. Because it stores energy well, lithium is used to make batteries. Lithium is especially useful in the kind of batteries that go into electric vehicles and renewable energy systems.

Traditional Lithium Extraction

Traditionally, lithium is extracted from rock or pumped from underground brine into big pools where it sits under the sun. The water in the brine evaporates over time, leaving behind lithium and other salts. This method can take a long time — sometimes over a year — and uses a lot of water, which isn’t good for the environment.

What is Direct Lithium Extraction?

Direct Lithium Extraction (DLE) is a modern technique that speeds up the process of getting lithium from brine. Instead of waiting for water to evaporate, DLE uses special filters or chemicals to pull lithium out of the brine much faster. This method is not only quicker but also more efficient, meaning it can get more lithium out of the same amount of brine.

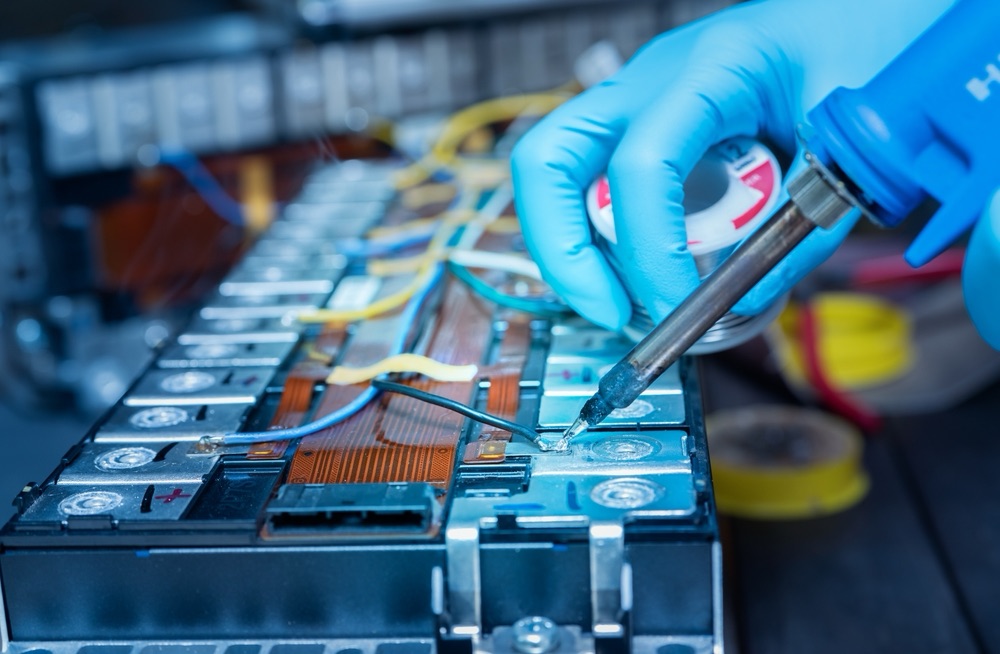

How Does DLE Work?

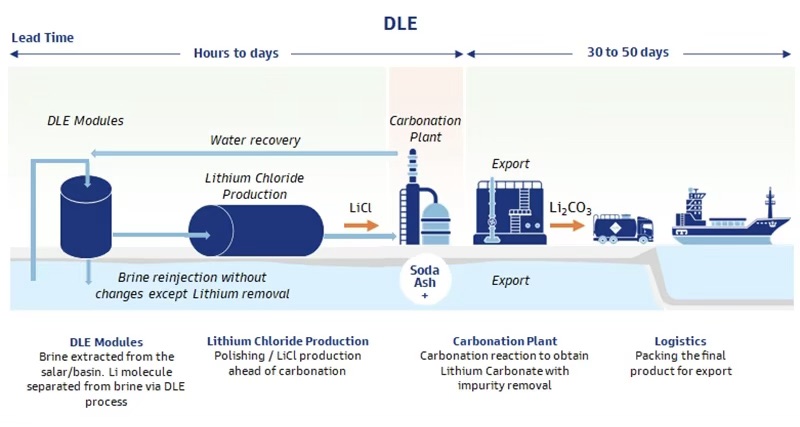

Here’s a simple way to think about DLE: Imagine you have a sponge that only soaks up water, not mud. In DLE, scientists use materials that act like a sponge for lithium. They put these materials into the brine, and they quickly soak up the lithium. Then, they remove the materials and extract the lithium from them. This process can be done in a few hours or days, not months or years like the old methods.

Benefits of DLE

Environmentally Friendly: DLE uses less water than traditional methods and doesn’t need big evaporation ponds that take up a lot of land and disrupt local ecosystems.

Faster Production: Since DLE can extract lithium much faster, it means companies can produce lithium more quickly to meet growing demands, especially as more people start using electric cars.

Higher Quality Lithium: DLE can often produce purer lithium, which is better for making high-quality batteries.

Examples of DLE in Action

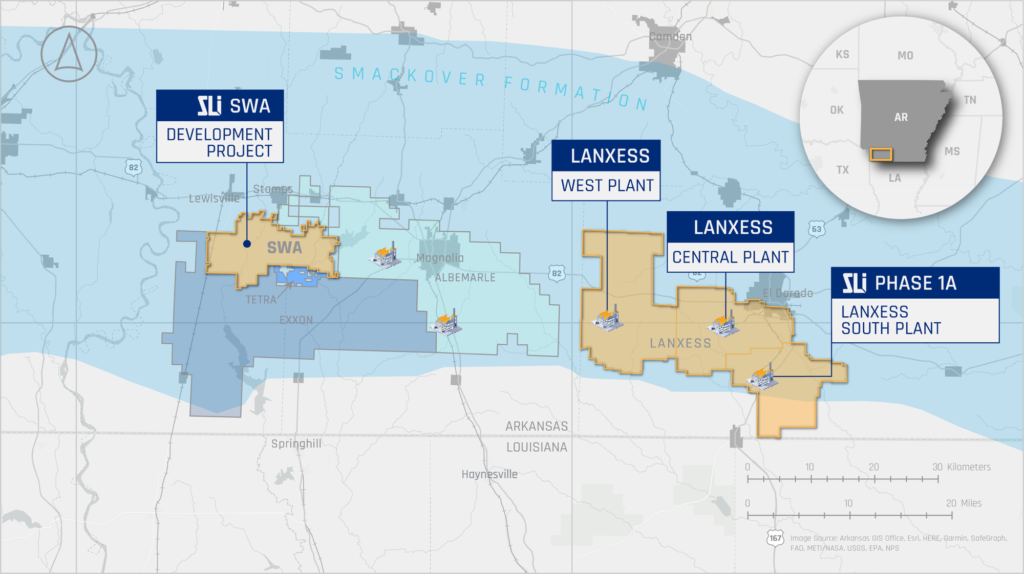

Several companies are leading the way in using DLE. For example, Standard Lithium in Arkansas, USA, uses DLE to extract lithium from brine. They work right next to a place that gets bromine from brine, using some of the same equipment and adding their special lithium-extracting technology.

Another example is EnergyX, which has developed a special kind of filter that captures lithium from brine. They are testing this technology in places like Bolivia, which has one of the largest reserves of lithium in the world.

The Future of Lithium Extraction

As we look to the future, technologies like DLE are expected to become more common. They make it easier and less harmful to the environment to get the lithium we need for our gadgets and cars. This is important because as the world tries to use more renewable energy and electric vehicles, the demand for lithium is going to keep growing.

Direct Lithium Extraction is an exciting development in mining technology, offering a faster, cleaner, and more efficient way to meet the world’s growing lithium needs. By understanding and improving technologies like DLE, we can ensure that our move towards a more sustainable future is successful and responsible.

If you want to learn more about existing and emerging EV Battery Technologies check out this interview by Vivas Kumar, the former battery supply chain manager at Tesla.